20 Years Construction Machinery Parts Supplier in Manufacturing Cemented Carbide Production - KOIHO

Tungsten Carbide Waterjet Nozzles for Precision Waterjet Cutter

Picture yourself standing in front of a powerful waterjet cutter, ready to take on any material with precision and speed. Now, imagine equipping it with a Tungsten Carbide Waterjet Nozzle, a tool so durable and efficient that it transforms the way you cut with its outstanding performance. With each slice and each curve, you feel the satisfaction of knowing you have the best tool in your hands, delivering crisp cuts and flawless results every time.

Ultra-Durable Precision Cutting Nozzles

Long-lasting Tungsten Carbide Waterjet Nozzles for Precision Waterjet Cutters, providing superior wear and corrosion resistance for high efficiency and extended tool life. Recommended for submerged oil centrifugal pumps, wastewater treatment pumps, PDC drill bits, and more. Choose from a variety of grades and sizes to suit your specific application needs.

● Long-lasting

● Versatile

● Tough

● Reliable

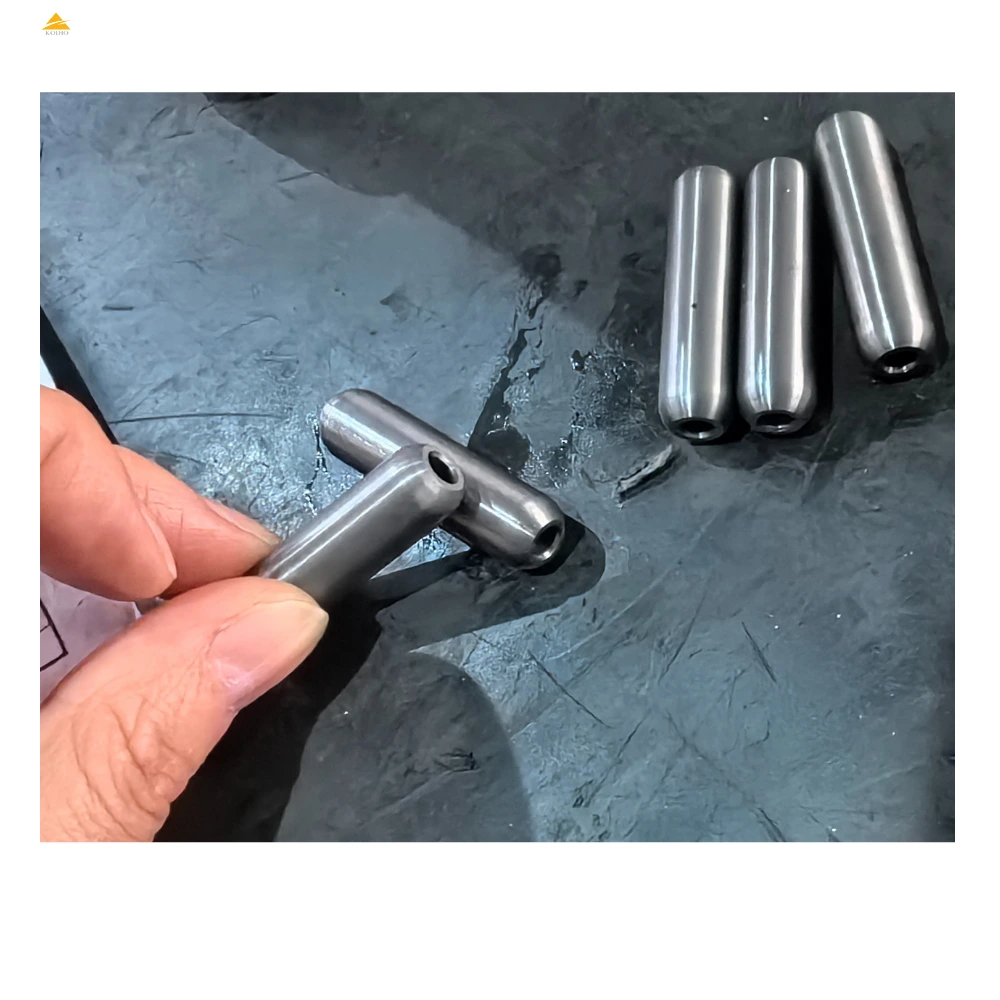

Product Display

Durable and Efficient Nozzles:

Precision cutting with durability

Tungsten Carbide Waterjet Nozzles for Precision Waterjet Cutter are high-quality components that provide superior wear resistance, impact resistance, and thermal shock resistance. These carbide nozzles are suitable for use in waterjet cutters, drilling bits, and other high-pressure applications in industries such as petroleum, chemical, and mechanical. The optimal strength and toughness of these carbide nozzles make them ideal for prolonging the life of tools and increasing work efficiency in demanding working conditions.

◎ Superior Wear Resistance

◎ Corrosion Resistance

◎ High Precision Cutting

Application Scenario

Material Introduction

Crafted from high-quality tungsten carbide, the waterjet nozzles for precision waterjet cutters boast superior wear and corrosion resistance, ensuring a long product lifespan. These precision components undergo diamond wheel grinding and spark machining for precise dimension accuracy and specified surface roughness. Ideal for submerged oil pumps, electric pumps, and various mechanical components, these carbide nozzles are designed to enhance work efficiency and tool longevity in complex and demanding working conditions.

◎ material introduction 1

◎ material introduction 2

◎ material introduction 3

FAQ